Operation USAF™

How do USAF™ cavitating ultrasonic transmitters work?

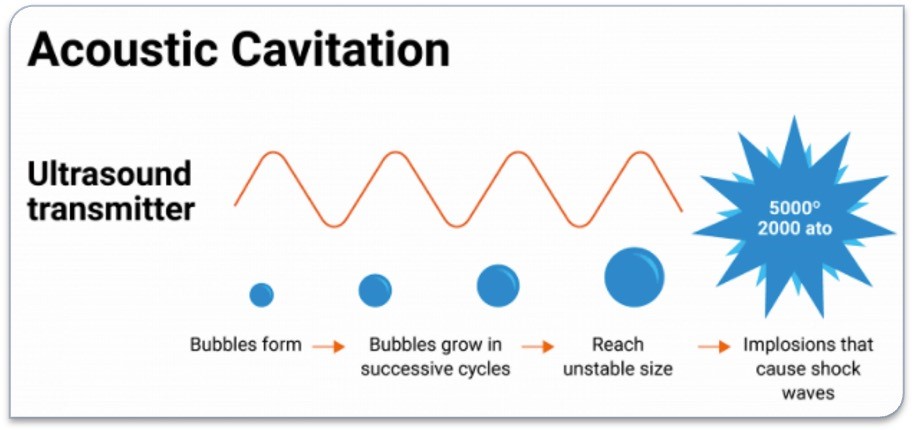

The cavitating ultrasonic emitters continuously send a very high frequency sound into the water, creating cavitation. Cavitation is a physical process in which gas bubbles form between water molecules. These gas bubbles get bigger and bigger due to the persistent sound, causing them to become unstable and implode. The imploding of the gas bubbles creates very powerful pressure waves that rupture the membranes of the microorganisms. This means the end of the micro-organisms in question.

As shown in the top figure, imploding causes a pressure wave of 2,000 bar. The pressure wave moves through the water at 1,250 m/s, destroying the micro-organisms present. Algae, for example, will die, sink to the bottom and lose their green colour over time. But other pathogens, such as fungi, bacteria and viruses, also do not escape the impact of the force of cavitation and will be killed off.

This is difficult to see with the human eye, which is why we made the video below, which clearly shows the impact of the pressure waves. The pressure waves only affect micro-organisms... and the aluminium foil because it is very thin ;-). These pressure waves have no impact on sails, walls, fish and mammals. In the short video below, you can see the impact after a very short time, however, our transmitters are usually on 24/7 and 365 days a year, imagine the result!

Advantages of using cavitating ultrasound transmitters at a glance:

- Basin water remains free of algae, the filters need to be cleaned less often and there are far fewer blockages in the pipes and drippers.

- By using ultrasonic transmitters, you counteract the formation of biofilm, and existing biofilm is broken down after the installation of our equipment.

- More yield and less wastage because the plants need to spend less energy defending themselves against bacteria, fungi and viruses in the water.

- USAF™ transmitters combined with hydrogen peroxide will give greatly improved results in combating pathogens and viruses. Because the membranes are already ruptured, the operation is much more efficient.

- Far fewer pesticides are needed, as water quality is greatly improved. In many cases, a cheaper and more environmentally friendly product is sufficient.

- Fertilisers in the drain water can be reused.

- Water is a major dispersant, using our cavitating ultrasonic water sanitiser makes this a thing of the past.

- Short payback period, as the plants yield more, have less waste, fertilisers can be reused and also (much) fewer pesticides need to be used.

- But above all, the stations unburden you and your staff by putting the water in 'good hands'.